Building your own Murphy bed at home is something I learned when I needed more room but didn’t want to get rid of the things I loved.

A Murphy bed is a smart way to save space, and you can make one even if you’re not a pro.

In this guide, I’ll show you what you need, how to plan the project, and the steps to put the bed together safely.

You’ll see how to measure your space, build the frame, attach the hardware, and mount it to the wall. I’ll also share mistakes to avoid and simple tips that keep the bed working well over time.

By the end, you’ll know exactly what to do and feel ready to build a Murphy bed that fits your home and your budget.

What You Need Before You Start Building a Murphy Bed

Before you begin building a Murphy bed, it helps to get everything in place. This makes the project smoother and saves you time later.

- Gather tools like a drill, screws, a level, a tape measure, wood panels, and Murphy bed hardware.

- Set up a clean, open workspace with good lighting and enough room to move around safely.

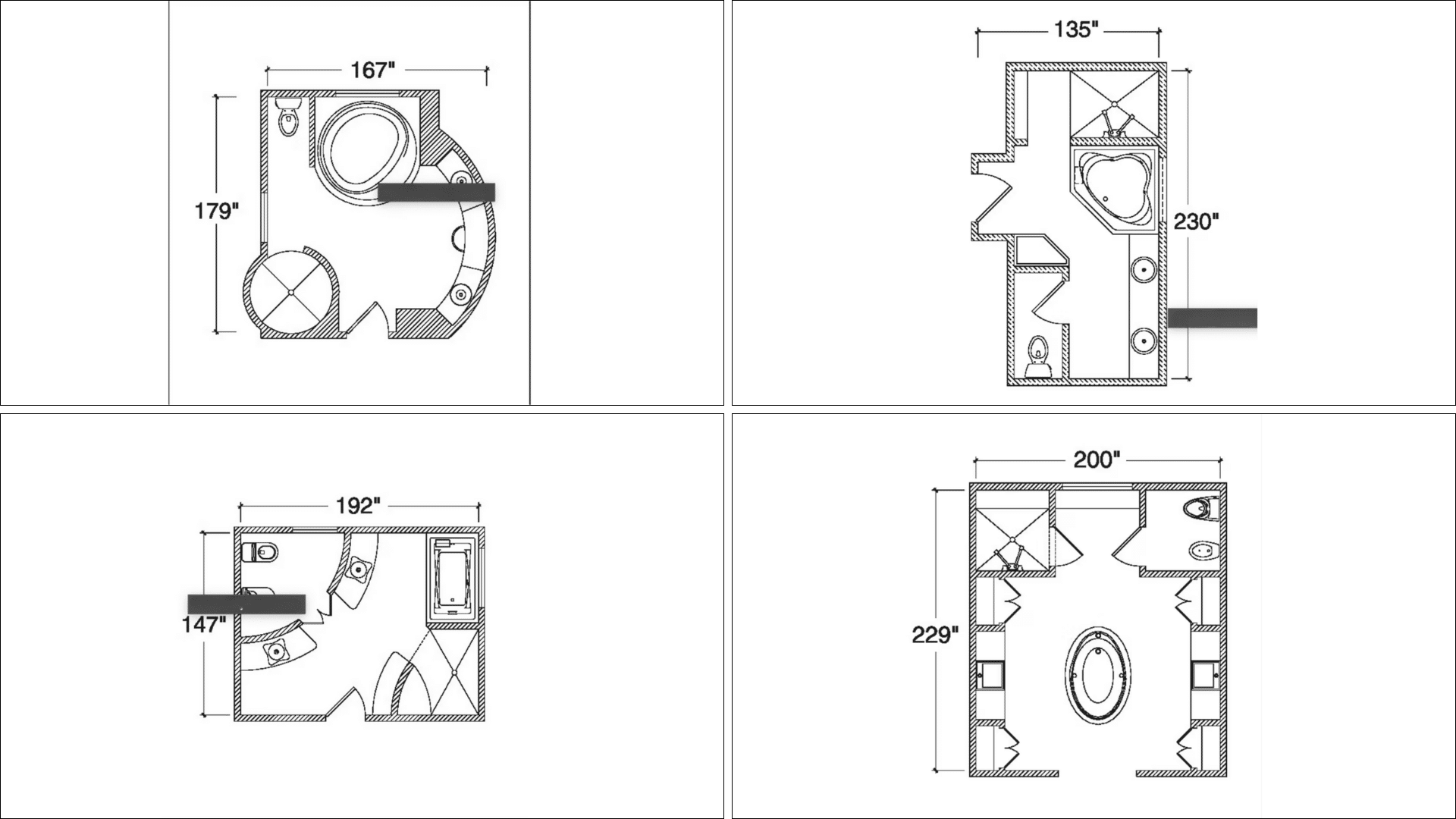

- Pick a spot with solid wall support, enough floor space for the bed to open, and no blocked outlets.

- Plan your budget based on wood, hardware, and finishes, and set aside enough time to complete each step without rushing.

Step-By-Step Guide to Building a DIY Murphy Bed

These steps walk you through each part of the build in a clear and simple way. It breaks the project into manageable tasks so you can follow along with confidence.

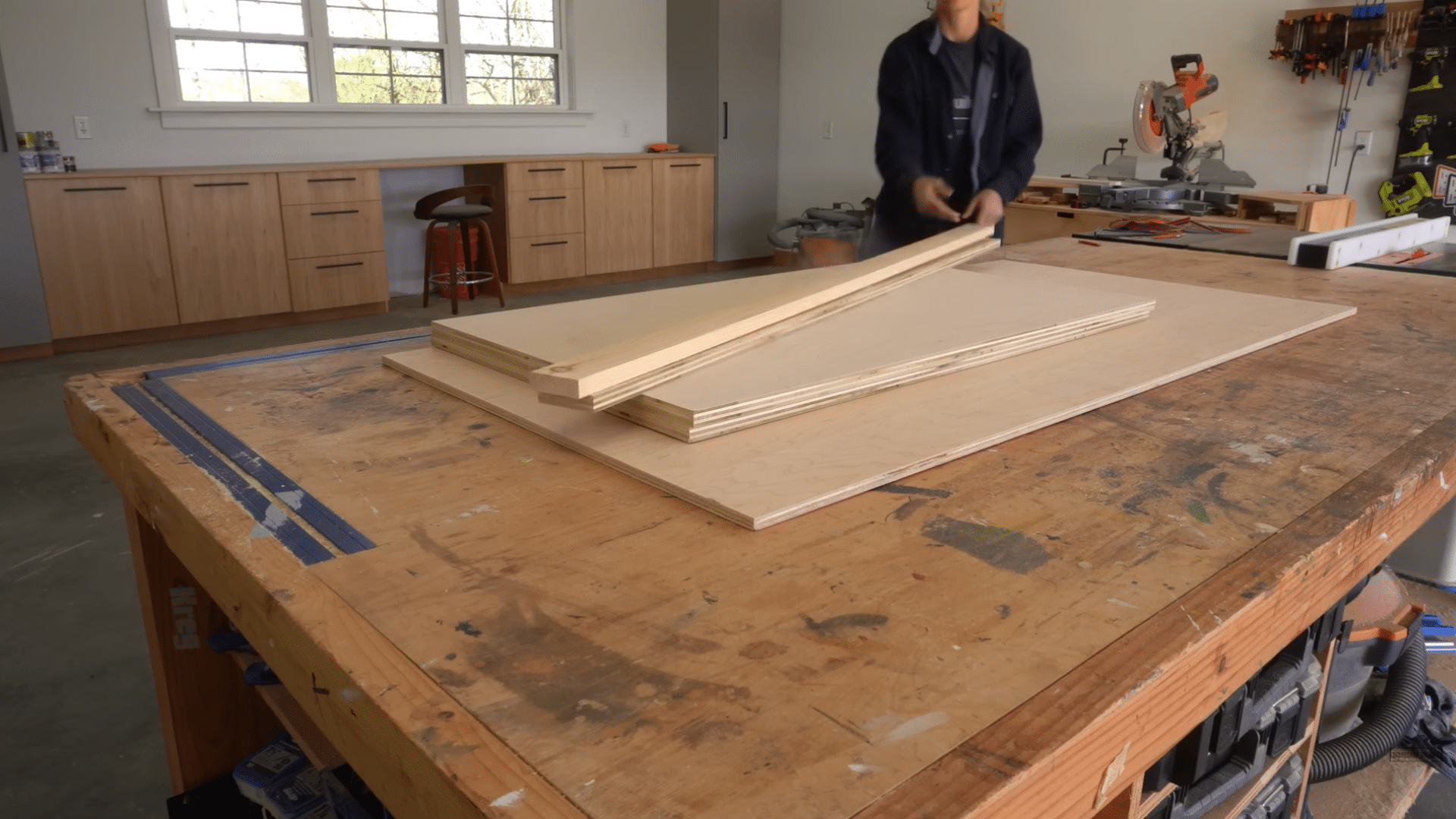

Step 1: Cut the Main Cabinet Panels

The build begins by cutting all the plywood pieces needed for the main cabinet. This includes two side panels made from ¾-inch plywood and a large back panel made from ½-inch plywood.

A 1×3 board and a long plywood strip are also cut to serve as internal supports between the side panels.

Since the front and top of the cabinet will remain visible, those edges are fully edge-banded and sanded for a clean finish.

These cuts form the foundation of the cabinet frame, and accurate sizing helps the rest of the project come together smoothly with proper alignment throughout.

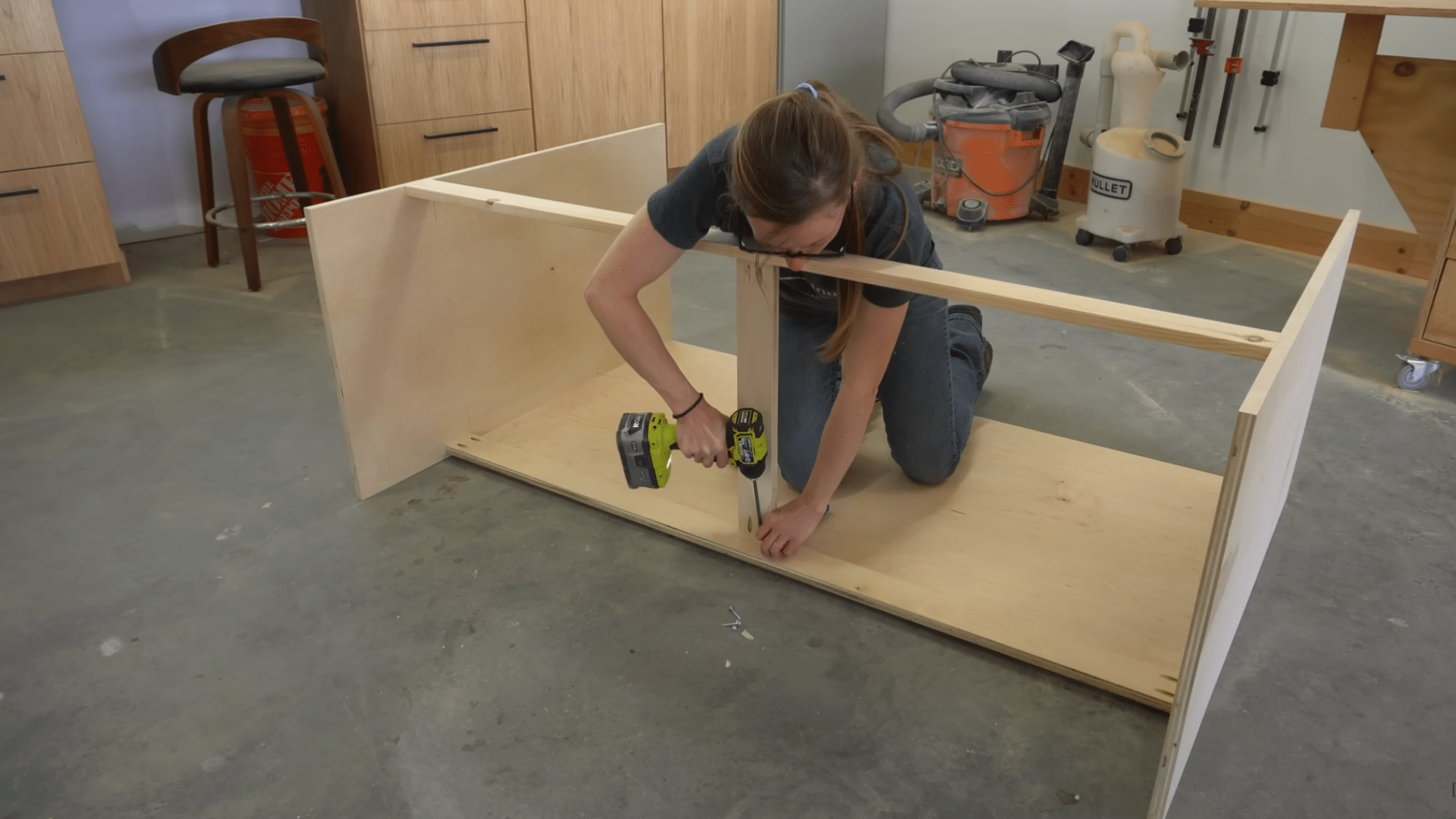

Step 2: Assemble the Main Cabinet Frame

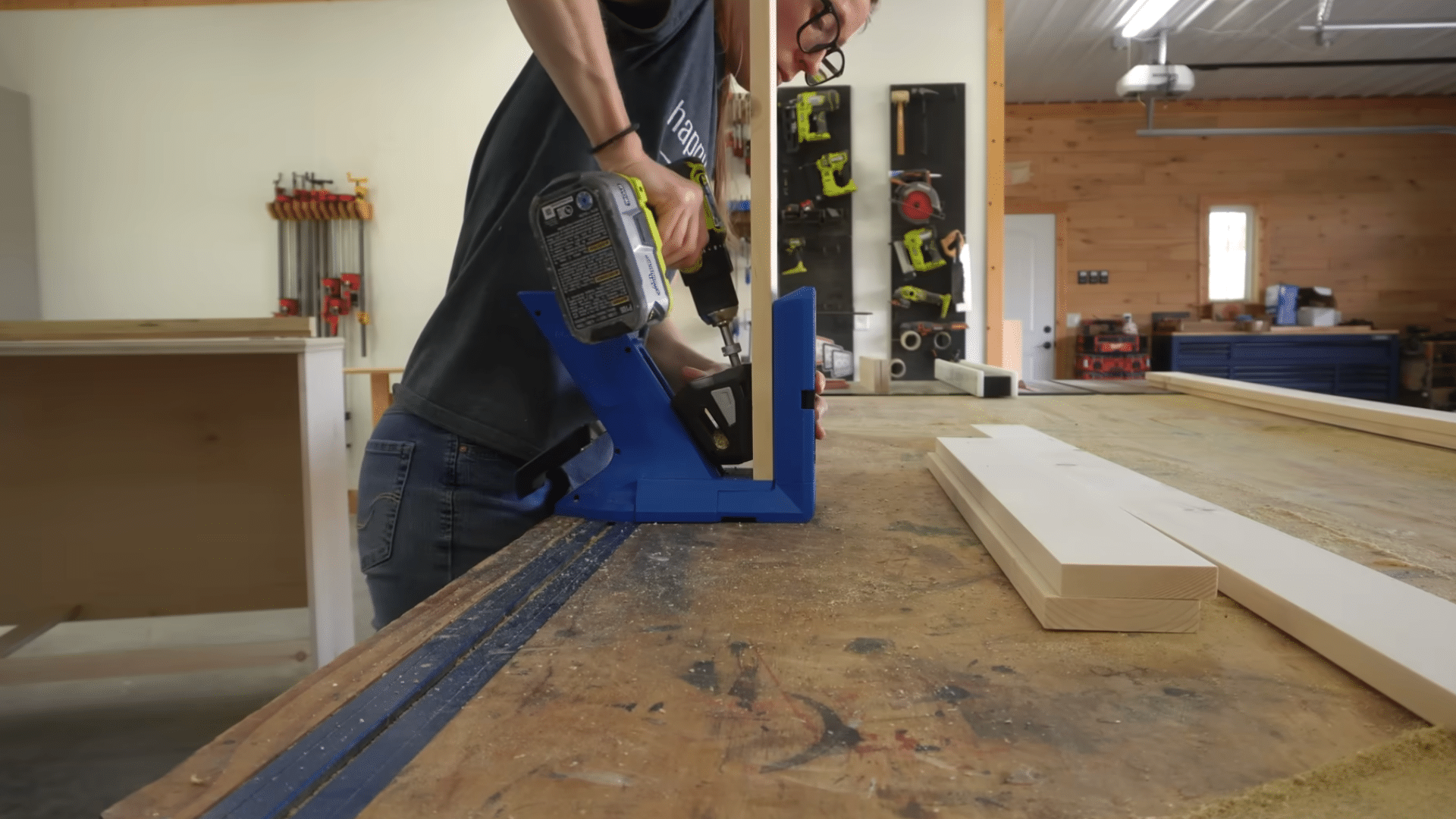

The next step is assembling the cabinet using pocket holes and screws, with the solid 1×3 placed at the front and the plywood support strip positioned at the back for stability.

Once everything is squared and aligned, the back panel is secured to the support strip with screws.

This assembly forms the main cabinet shell, which will hold all the moving parts of the Murphy bed.

A strong and well-secured frame helps prevent shifting, gaps, and uneven pressure once the bed is in use, making tight connections essential for long-term stability.

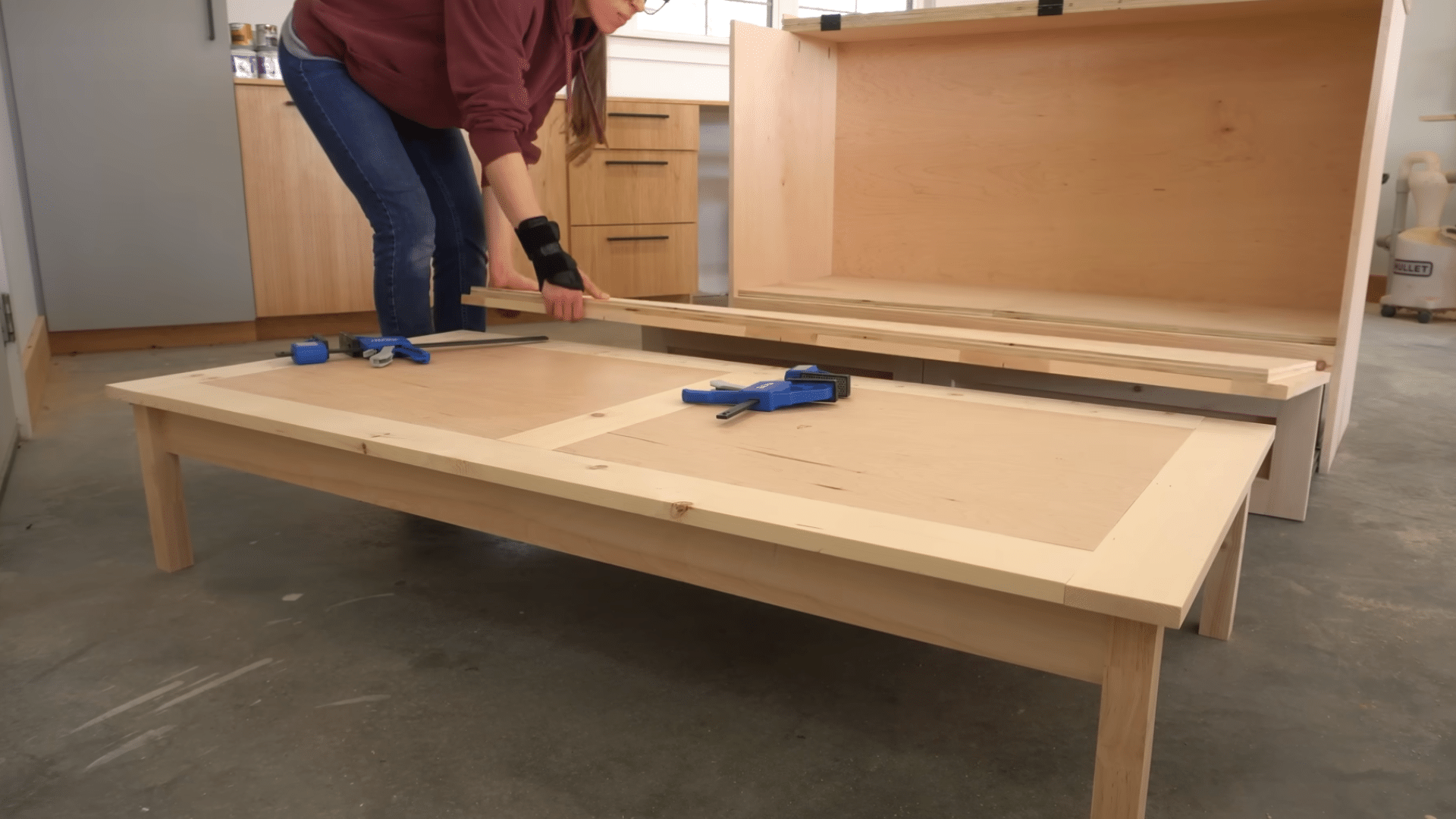

Step 3: Build and Split the Top Panel

To create the top section, one solid panel is cut, and a trim is attached around the front and sides using glue and nails.

Care is taken to avoid placing nails along the line where the top will later be cut.

After the glue has dried, the panel is ripped down the center so the front half can flip forward while the back half remains fixed to the cabinet.

This approach keeps the top looking seamless while allowing enough clearance for the folding bed sections. The trim helps conceal small gaps and gives the cabinet a polished, finished appearance.

Step 4: Add Interior Supports and Bottom Panels

Inside the cabinet, a strong support strip is added running from the front to the back to anchor the foldout frames.

For the bottom surface, two smaller plywood panels are used instead of one large piece to make efficient use of leftover materials.

Both panels are attached with pocket holes to the side panels and secured with screws to the support strip. Even though the bottom is made from multiple pieces, the support ensures everything stays level and strong.

This internal structure creates a reliable base for the folding mechanism and evenly distributes weight during use.

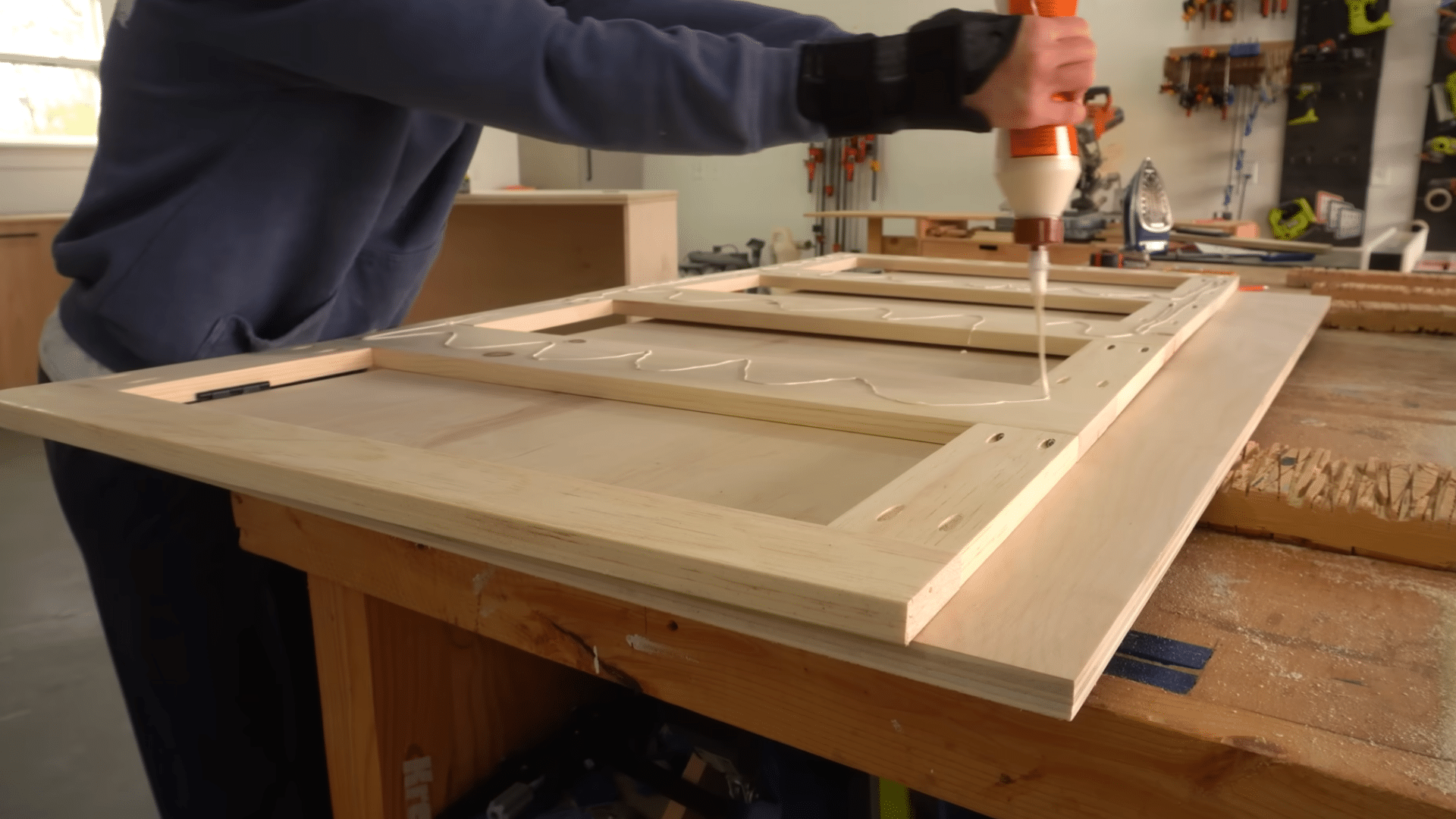

Step 5: Build the Faux Door Front Frame

The front of the Murphy bed is designed to look like four cabinet doors, even though it functions as one large fold-down panel.

This is done by building a frame using 1×3 boards for the outer edges and a 1×6 board in the center. A curved groove is cut down the middle of the 1×6 to mimic the appearance of two doors meeting.

Pocket holes are used to assemble the frame, and although the frame may bow slightly during assembly, it flattens once attached to the backer panel.

This method creates a clean, furniture-style look when the bed is closed.

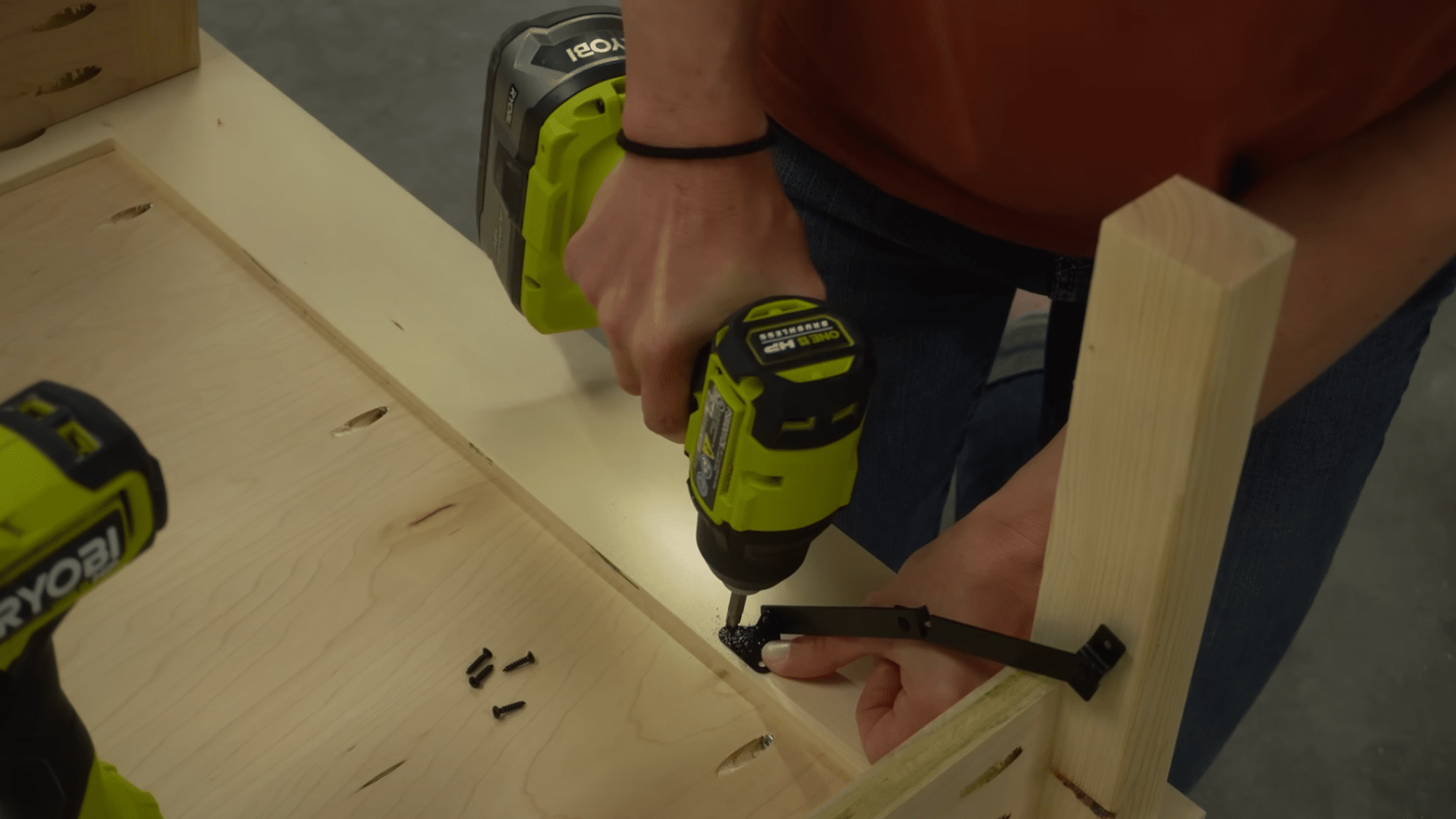

Step 6: Add the Backer Panel and Hinges to the Door Section

A ¾-inch plywood backer panel is cut slightly smaller than the frame so it overlaps the cabinet edges once installed. Three butt hinges are installed along one long edge of the plywood.

After the hinges are secured, the frame is glued and clamped onto the backer panel.

Once dry, this creates a strong, stable fold-down front that supports the mattress and handles most of the motion when the bed opens and closes.

Building this section with even pressure and solid attachment allows the bed to fold smoothly and keeps the front visually clean and sturdy.

Step 7: Build the Second Foldout Frame with Legs

The second foldout frame is built using 1×4 boards and ½-inch plywood inserts, which is helpful if full sheets of ¾-inch plywood aren’t available.

The strength of the frame is tested by placing weight at the center, and it holds well because the mattress’s weight is spread across the full panel during use.

Foldable legs are attached with hinges so they can swing out when the bed is opened.

Locking supports are added to the legs to improve stability and prevent wobbling, making the structure feel stronger and more secure.

Step 8: Install Drawer Slides and Build the Drawer Box

Drawer slides are installed about ½ inch above the bottom of the cabinet.

While they do not carry the bed’s full weight, they offer support to the foldout panel during movement and help keep everything level.

The drawer box is built from ¾-inch plywood pieces with a ½-inch plywood bottom attached. Once the drawer is assembled, it is slid into the cabinet to ensure smooth operation.

Besides offering storage, the drawer also stabilizes the middle foldout frame and helps it rest evenly as the bed moves from closed to open.

Step 9: Add the Drawer Front and Connect the Foldout Frames

The drawer front is built using a 1×6 board in the center with 1×3 boards on each side to match the look of the faux door panel above.

It is spaced ¼ inch above the floor to allow smooth movement. With the drawer installed, its top surface helps support the middle foldout frame during hinge installation.

Three hinges are attached between the two foldout panels, and the middle section is connected to the cabinet.

Testing the bed at this point confirms that the folding action is smooth and that the mattress fits properly without pressure points.

Step 10: Add Finishing Touches and Test the Bed

To finish the project, add latches inside the cabinet to keep the front panel closed when upright.

Apply two coats of Minwax Polycrylic to seal and protect the wood. Then add knobs to the doors and pulls to the drawer.

For safety, lock the leg supports and add shims under the drawer front whenever extra stability is needed.

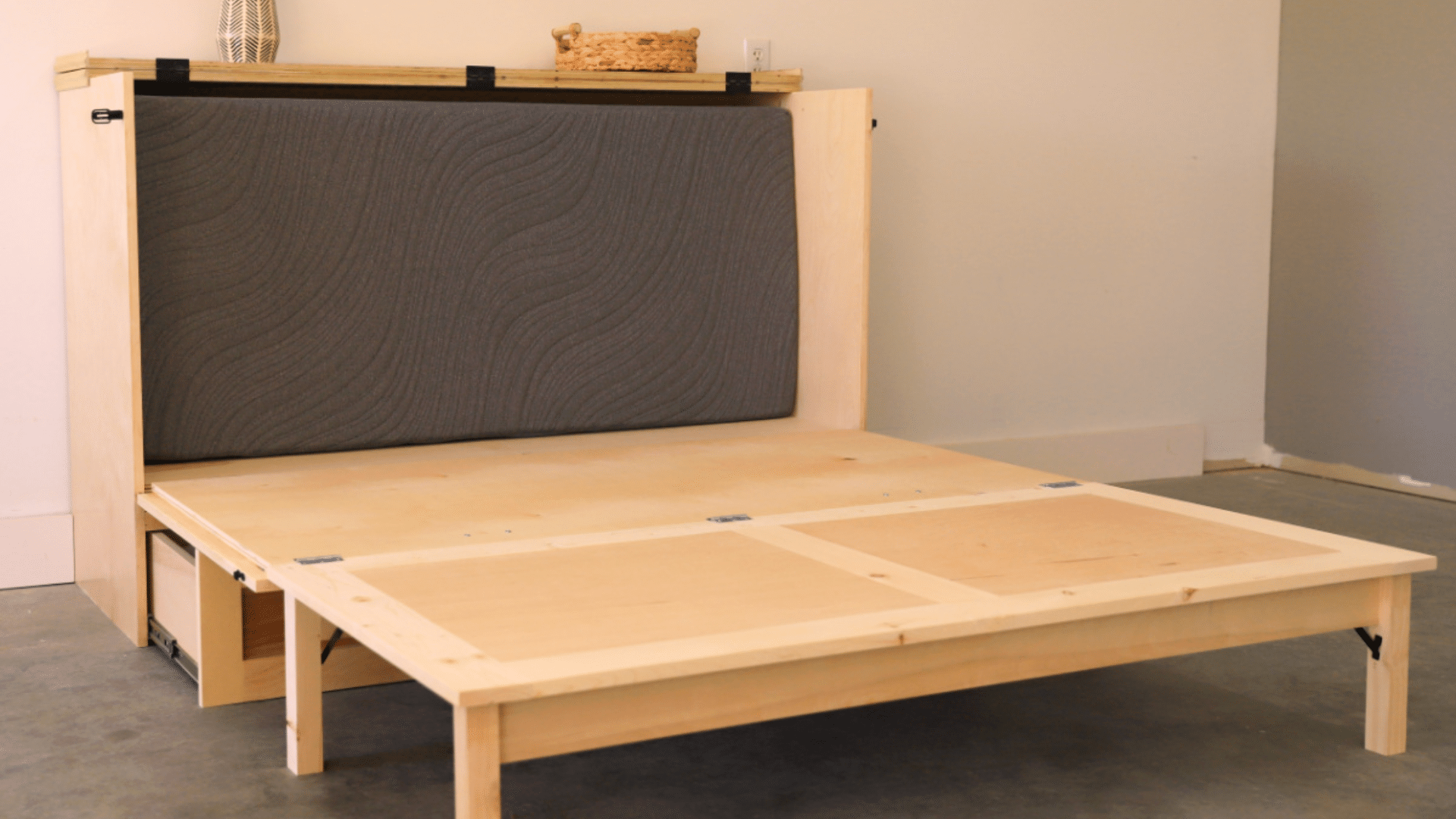

After everything dried, test the bed with the mattress in place. The bed opened evenly, folded cleanly, and felt sturdy and secure.

This tutorial is based on a helpful video by Shara Woodshop Diaries. You can check out the original video on their YouTube channel here or watch it below.

Common Mistakes to Avoid

Common mistakes can slow you down or make your Murphy bed unsafe, so it helps to spot them early.

Skipping measurements is one of the biggest issues, because even a small error can throw off the frame or keep the bed from folding the way it should.

Using weak hardware is another problem, since the bed needs strong support to open and close safely.

Many people also mount the bed to the wall the wrong way, which can lead to loose brackets or damage over time.

Another mistake is overlooking safety features like locking hinges or proper weight balance. Paying attention to these details keeps the bed sturdy and makes the whole project go smoothly.

Tips to Keep Your Murphy Bed Working Smoothly

These simple habits help your Murphy bed stay safe, steady, and easy to use. A little regular care can prevent problems later.

- Check all screws, brackets, and hardware every few months to keep them tight and secure.

- Lubricate the hinges or moving parts if the bed starts to feel stiff.

- Keep the weight on the bed balanced and avoid placing heavy items at one end.

- Clean around the frame and wall area so dust doesn’t build up in the hardware.

- Test the folding motion now and then to make sure everything opens and closes smoothly.

Conclusion

Building your own Murphy bed at home may feel like a big project at first, but once you break it into clear steps, it becomes something you can handle with confidence.

I’ve shared the tools, planning steps, building process, and common mistakes to help you get started with confidence.

When you take your time and follow each step with care, you end up with a bed that saves space, works smoothly, and fits your home perfectly.

If you’re ready to free up more room and add something useful to your space, this project is worth trying.

You’ll not only save money but also enjoy the feeling of making something that improves your everyday life.